Quality

The company monitors its performance in the key areas such as internal and external PPM and on-time delivery for the outputs of customer related processes. By establishing goals and continuously improving to achieve them, the company ensures customer satisfaction.

We are constantly looking to find ways to streamline manufacturing to cut production time and to reduce cost per part. A.B.M. will translate innovative ideas into workable technology to gain an advantage for the customer's benefit.

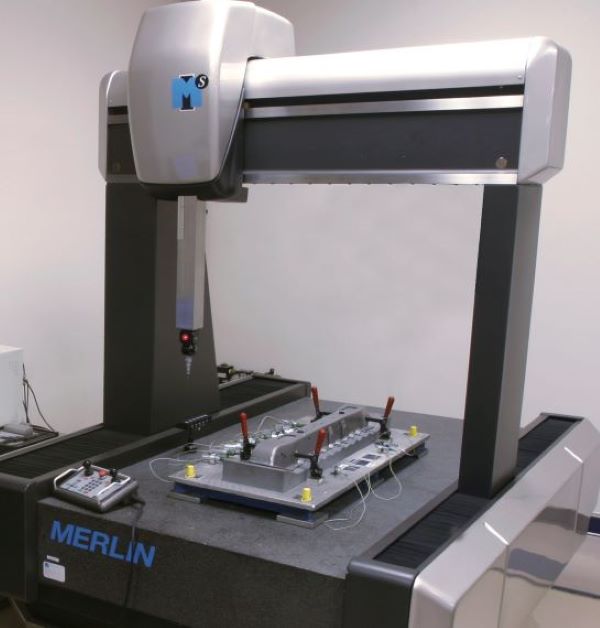

Our quality engineers are actively involved at the planning stage of all new projects, providing valuable contributions to GD & T analysis, fixture design and process manufacturing versus process capability concepts.

Providing our customers with Tooling Qualification Reports, full AIAG, PPAP's and any further documents requested, has been a part of our service for more than a decade.

Our manufacturing division is backed up by Quality Assurance and Inventory Control to ensure compliance with all customer specifications, and we are ISO 9001 compliant and IATF 16949 certified.

A.B.M. Tool & Die strives to meet or exceed our customers’ requirements through the supply of high-quality metal stampings, assemblies, and tooling.